Making wing material that floats is a fairly simple process. To start you need the following items:

1. A pressing table

1. A pressing table

2. Iron (Hobby or regular pressing iron)

3. Scissors

4. Heat-n-Bond

5. Netting or Polypropylene (PP) Hair

6. Polyethylene foam sheeting

7. Alcohol ink for additional coloring

8. Teflon Pressing Pad

1. A pressing table

1. A pressing table2. Iron (Hobby or regular pressing iron)

3. Scissors

4. Heat-n-Bond

5. Netting or Polypropylene (PP) Hair

6. Polyethylene foam sheeting

7. Alcohol ink for additional coloring

8. Teflon Pressing Pad

The next step in the process is to determine the color of the wing material to be produced. The wing material can be colored with alcohol ink or just the use colored netting or hair. If ink is to be used it is best to apply it to polyethylene foam sheeting or in some cases directly to the Heat-n-bond material. If ink is used color the entire sheet of material to be used.

After coloring whatever material you are using cut a sheet of Heat-n-bond twice the size of the wing material to be made and lay it out with the colored sheet on top. Then add the netting or PP hair. In this sample the colored sheet is red and black netting is laying on the bottom half with PP black hair on the top half laid out in a random pattern. The Heat-n-Bond is now ready for folding after application of a second colored polyethylene sheet.

After coloring whatever material you are using cut a sheet of Heat-n-bond twice the size of the wing material to be made and lay it out with the colored sheet on top. Then add the netting or PP hair. In this sample the colored sheet is red and black netting is laying on the bottom half with PP black hair on the top half laid out in a random pattern. The Heat-n-Bond is now ready for folding after application of a second colored polyethylene sheet.  With the second sheet applied fold the Heat-n-Bond over to form a sandwich. The two sheets of foam, netting, and hair are all inside the folded Heat-n-Bond. The iron has been set on the hottest setting and the sandwich placed on a Teflon pressing pad to avoid sticking of the over lapping edges of the Heat-n-Bond.

With the second sheet applied fold the Heat-n-Bond over to form a sandwich. The two sheets of foam, netting, and hair are all inside the folded Heat-n-Bond. The iron has been set on the hottest setting and the sandwich placed on a Teflon pressing pad to avoid sticking of the over lapping edges of the Heat-n-Bond.  Using the iron press the Heat-n-Bond from the fold to the outer edge until one side is completely flattened. Then turn the sandwich over and press the other side making sure that all edges on both sides are covered. Set the pressed sandwich aside and let it cool completely.

Using the iron press the Heat-n-Bond from the fold to the outer edge until one side is completely flattened. Then turn the sandwich over and press the other side making sure that all edges on both sides are covered. Set the pressed sandwich aside and let it cool completely.

After the sandwich has cooled completely peal back one side of the Heat-n-Bond. Then peal the other side from the fold to remove the backing from the now completed wing material.

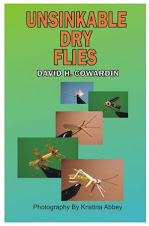

The finished material will look like these other examples we have made. If you do not use the polyethylene sheeting, as we did above, you should add another sandwich layer of Heat-n-bond to provide sufficient strength and prevent the wing material from tearing. It should be noted that you can also add glitter, flash, tinsel, or other attractor materials to make the finished wings more luminous.

Nice job, david.

ReplyDeleteI thought I found out something spectacular but you did it some time earlier.

Its nice to try using clingfilm or stretchfilm in these sandwiches. I wrote an article in dutch on my website and there is some conversation on the ffft forum board in england.

www.maartenvaneijk.weebly.com

http://www.flyfishing-and-flytying.co.uk/forums/viewthread/894/